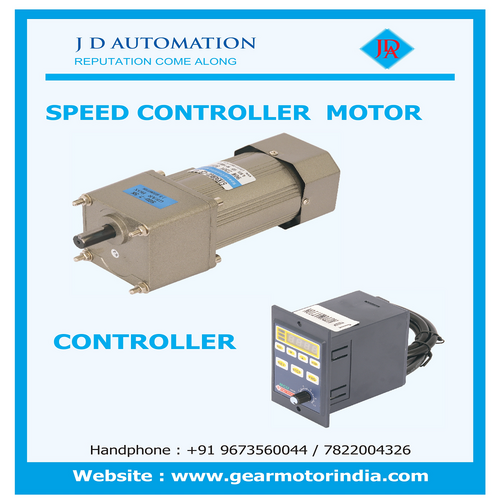

40W Speed Controller Standard Induction Motor

Product Details:

- Rated Frequency 50/60 Hz

- Cooling Method Air Cooled

- Sealed Type Totally Enclosed

- Pressure Atmospheric

- Power Rating 40W

- Motor Type Standard Induction Motor

- Efficacy High

- Click to View more

X

40W Speed Controller Standard Induction Motor Product Specifications

- 40W

- 1400 rpm

- 220V

- 145mm x 90mm x 75mm

- <50 dB

- AC

- Single Phase

- 12mm

- Speed adjustable, overload protected

- Ball Bearing

- 220V

- Capacitor Start

- IP54

- 0.27 Nm

- IEC

- 4

- -10C to 40C

- 0.05 HP

- Black & Silver

- 40W

- High

- IP54

- 40W

- Standard Induction Motor

- Atmospheric

- Speed Controller Induction Motor

- Totally Enclosed

- Air Cooled

- 50/60 Hz

- 50/60 Hz

- 2.5 kg

- Base Mounted

Product Description

Specification

| Brand | J D AUTOMATION |

| Power | 40W |

| Speed | 90 to 1200 RPM |

| Voltage | 230V |

| Usage/Application | Industrial |

| Phase | Single Phase |

| Frame Size | 90 x 90mm |

| Frequency | 50 Hz |

| Insulation Class | E To A |

| Current | 0.53A |

| Starting Torque Motor Shaft | 1.4 Nm |

| Model Name/Number | J90IG40N-SC |

| Permissible Torque | 0.3 Nm at 1200 RPM and 0.14 Nm at 90 RPM |

High Efficiency and Superior Durability

This motor boasts a robust aluminum housing and IP54 protection, making it resilient to dust and moisture, even in challenging industrial environments. Its ball bearings and air-cooled system contribute to smooth and efficient operation, ensuring a service factor of 1.0 and longevity under continuous use.

Versatile Applications

Designed for conveyor systems, industrial machines, and packaging equipment, the standard induction motor caters to a broad spectrum of automation and material handling needs. Its precise analog speed control makes it suitable for processes demanding variable speeds and consistent torque output.

Easy Installation and Maintenance

Featuring base mounting and a totally enclosed design, the motor ensures straightforward installation in various industrial setups. The included 1-meter lead wire, along with the shaft diameter of 12mm, facilitates integration and routine maintenance, while noise emissions remain below 50 dB for a comfortable work environment.

FAQ's of 40W Speed Controller Standard Induction Motor:

Q: How does the analog speed controller adjust the motor speed?

A: The analog speed controller variably modifies the input to the motor, enabling precise speed adjustments from the rated 1400 rpm to meet specific application requirements such as conveyor speed or machine operation pace.Q: What are the main benefits of the IP54 rating for this motor?

A: The IP54 rating ensures reliable protection against dust ingress and water splashes, making the motor suitable for humid and dusty industrial environments without compromising efficiency or longevity.Q: When is it optimal to use the 40W Speed Controller Standard Induction Motor?

A: It is best utilized in continuous-duty industrial applications like conveyors and packaging equipment where consistent speed, durability, and overload protection are vital for operational stability.Q: Where can this motor be installed within a facility?

A: Thanks to its base-mounted design and totally enclosed structure, it can be securely fitted onto industrial machines, conveyor frames, or packaging systems in factories, warehouses, and processing plants.Q: What is the process for integrating the motor into a conveyor system?

A: Installation involves mounting the motor on the designated base, connecting it via its 1-meter lead wire to the power supply (220V, 50/60Hz), and configuring the analog controller for the required speed. The motor's overload and insulation features enhance safety during integration.Q: How does the motor's continuous duty cycle benefit industrial operations?

A: Continuous duty capability means the motor can run non-stop without overheating, supporting uninterrupted operation and increased productivity in automation or handling systems.Q: What steps should be taken to ensure optimal humidity tolerance?

A: To maintain performance, ensure the ambient humidity remains below 90% RH and the motor operates within -10C to 40C, as these conditions prevent condensation and potential electrical issues.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Feel free to

Feel free to Send Inquiry

Send Inquiry Send SMS

Send SMS