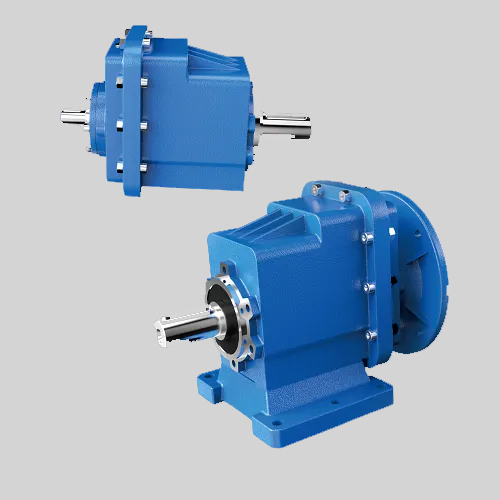

Worm Geared Motor

Product Details:

- Current Type AC

- Noise Level Low

- Torque 18 Nm to 850 Nm

- Starting Type Direct On Line

- Ambient Temperature -15C to +40C

- Standard IS/IEC 60034

- Power Rating 0.18 kW to 3.7 kW

- Click to View more

X

Worm Geared Motor Product Specifications

- IP54

- Worm Geared Motor

- 230V/415V

- Ball Bearing

- High Efficiency

- Blue/Grey

- Compact design, robust construction, high torque output

- 50 Hz

- 0.25 HP to 5 HP

- 14 rpm to 280 rpm

- 0.18 kW to 3.7 kW

- Customised as per model

- 2/4

- Totally Enclosed Fan Cooled (TEFC)

- 230V/415V

- Worm Geared Motor

- Single/Three Phase

- AC

- Customised as per model

- Low

- 18 Nm to 850 Nm

- Foot/Flange Mounting

- Direct On Line

- -15C to +40C

- IS/IEC 60034

- IP54

- 0.18 kW to 3.7 kW

- 0.18 kW to 3.7 kW

- Standard Atmospheric

- Approx. 8 kg to 48 kg

- 50 Hz

- Fan Cooled

Product Description

Specification

| Voltage | 230-415 V AC |

| Phase | Single Phase, 3 Phase |

| Mounting | Flange |

| Usage/Application | Industrial |

| Speed | 1500 RPM |

| Power | 180 W |

| Brand | J D Automation |

| Number Of Poles | 4 |

| Frame Size | 90 x 90mm |

| Frequency | 50/60 Hz |

Versatile Gear Ratios for Varied Applications

Our worm geared motors offer a wide selection of gear ratios, from 7.5:1 up to 100:1. This flexibility allows precise speed and torque customization, making them ideal for industries needing controlled motion or heavy-duty applications. Adaptability enables them to excel in conveyors, material handling, and machinery, supporting both custom and standard requirements.

Designed for Durability and Efficiency

Constructed with robust cast iron or lightweight aluminium housings, these motors guarantee strength and corrosion resistance. Lubricated with oil for smooth operation, the motors maintain low noise and ensure longevity even under continuous duty. The totally enclosed fan cooled (TEFC) design paired with IP54 protection keeps the motor safe from dust and moisture, supporting reliable use in demanding environments.

Precision Engineering for Superior Performance

With ball bearings and high torque output ranging from 18 Nm to 850 Nm, these worm geared motors deliver steady, vibration-controlled operation. Compliance with IS/IEC 60034 standards ensures consistent performance, while Class F insulation and direct-on-line starting provide additional safety and ease of integration. The compact, space-saving design helps optimize installation in varied setups.

FAQ's of Worm Geared Motor:

Q: How does the worm geared motor maintain high efficiency during continuous operation?

A: The motor is optimized for continuous (S1) duty and incorporates high-quality oil lubrication, robust ball bearings, and Class F insulation, ensuring smooth and efficient performance with minimal energy loss even over extended operational periods.Q: What is the process for selecting the appropriate gear ratio and output speed for my application?

A: Selection depends on your required speed and torque output. With gear ratios ranging from 7.5:1 to 100:1 and speeds from 14 to 280 rpm, consult the model specifications or speak with a supplier to match the motor's performance characteristics to your application's specific demands.Q: When is it advisable to choose cast iron over aluminium housing for the geared motor?

A: Cast iron housing is preferred in applications that demand maximum durability and resistance to mechanical impact, especially in harsh or heavy-duty environments. Aluminium offers lighter weight and is suitable for uses where ease of installation and corrosion resistance are priorities.Q: Where can these worm geared motors be installed and operated safely?

A: Thanks to their IP54 rating and TEFC (Totally Enclosed Fan Cooled) design, these motors can be installed indoors or in protected outdoor environments where exposure to dust and moderate moisture is possible. Always follow recommended guidelines for ambient temperature and atmospheric conditions.Q: How does the totally enclosed fan cooled (TEFC) design benefit the motor's lifespan?

A: The TEFC design protects internal components from dust, moisture, and other contaminants while maintaining optimum operating temperatures. This leads to reduced wear, lower maintenance needs, and a longer service life, especially in industrial settings.Q: What are the usual usage scenarios for these worm geared motors?

A: These motors are especially suitable for conveyors, mixers, lifting devices, and automated machinery where consistent and reliable torque is crucial. Their compact construction and high torque output make them versatile for a wide array of industrial and manufacturing processes.Q: What are the primary benefits of choosing this worm geared motor?

A: The main advantages include high efficiency, customizable mounting and shaft options, low noise, robust construction, adherence to international standards, and suitability for a range of power and speed requirements, making them a dependable choice for both light and heavy-duty applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Feel free to

Feel free to Send Inquiry

Send Inquiry Send SMS

Send SMS